Rejuvenated control technology brings Southern German small-scale power stations up to current state of technology

Bild: © Troyer

It was high time to take action. The control equipment in some of the 17 small-scale power stations owned by energy provider naturenergie was falling well below current standards for water power utilisation. To remedy the situation, the operator initiated the modernisation of the control systems in six of their facilities. The contract for the project was awarded to South Tyrolean hydropower all-rounder Troyer. From 2022 to 2024 Troyer’s engineers proceeded to bring the facilities up to the latest technical standard, all to the full satisfaction of the operator. Further projects to modernise existing control systems are already in the pipeline.

When it comes to hydropower technology, longevity is key. Turbines, hydraulic steelwork constructions or penstocks, if implemented by well-established industry providers, will typically last for decades. Unfortunately, the same does not apply to a specific component that modern facilities simply can’t do without: the control system, especially the operating software. Yesterday’s high-end (or at least state-of-the-art) solution may already be outdated or even obsolete by tomorrow. “The typical lifespan quoted for control system components is about 30 years,” says Tobia Walpoth, who heads up Troyer’s Automation department. “But that applies only to the PLC and the control panels, not the software. In fact, the operating software is increasingly short-lived.” Tobia Walpoth knows what he is talking about. Over the past few years, he and his team have equipped numerous hydropower stations with latest-generation control equipment. For many years Troyer’s control solutions have ranked among the most advanced technologies the European hydropower industry has to offer. In a recent demonstration of their competence, the South Tyrolean experts modernised a series of power facilities in Germany’s Black Forest region.

A colourful mix of control systems

The group of small-scale hydropower stations operated by naturenergie hochrhein AG comprises a total of 17 facilities. naturenergie owns them all, except for three, which they operate on behalf of third-party providers. In many respects the power stations, which are situated at various locations throughout the Black Forest region, could hardly be more diverse, as Tim Schöne, naturenergie hochrhein’s team leader for small-scale power stations, explains: “It’s definitely a colourful bunch. Some of the facilities are around 100 years old and have always belonged to our company. Some are part of old industrial works, but there are some new ones as well. The forebay configurations are also wildly dissimilar. As for the control systems, there was a whole pot-pourri of designs and formats to deal with. It’s been a growing challenge for our team in recent years.” The consequences, as Tim Schöne points out, include rising maintenance and storage costs, extremely limited remote access options, and problems finding replacement parts for some of the systems. “In some cases the manufacturers stopped selling replacement parts ten years ago. It took a lot of creativity and improvisation effort to keep the facilities operating at least on a somewhat economical level.” Faced with these challenges, the operators decided to first modernise and unify the control equipment in five of their own facilities and, pending the owner’s go-ahead, in one of the third-party owned ones. In 2020, they launched an EU-wide invitation to tender for “Project Standardisation of Control and Electrical Equipment”, with eminent South Tyrolean hydropower all-rounder Troyer eventually winning the contract as the best bidder.

New technology for six power stations

Troyer was not exactly unknown to the experienced hydropower operators from Southern Germany. In 2015 and 2016, the South Tyrolean specialists had already provided the entire equipment for two of the newer power stations, i.e. the facilities in Mambach and Hottingen. The components installed at that time included everything from the electromechanical componentry to the control system. Collaborating on this project, as Tim Schöne recalls, was an excellent experience.

In 2022, the Troyer team set to work on the new project. The modernisation work focussed specifically on small-scale power stations Brennet, Maulburg I, Fahrnau, Hausen I and Atzenbach, as well as the Schopfheim facility, which naturenergie operate on behalf of a third-party provider. “Our job is basically to completely replace the electrical and control equipment at these facilities, both the main hardware as well as the sensors and actuators. We’ll also upgrade the visualisation software,” as project leader Pirmin Schneider explains. The project package included the control panels, high-voltage components, the 400-volt distributor, and the generator switchboard. Most of the existing control cabling could be reused. The way the experts handed them showed their true professionalism, as Tobia Walpoth recalls. “We had an electrician with more than 20 years of professional experience in our team. He was a great example for our younger team members, showing them how a job well done pays off in the end. Once he’d disconnected a cable, he’d always label it properly before connecting it to the new terminal block. When we took the systems back into operation, there was not a single sensor that wouldn’t work straight away.”

Unification for state-of-the art operations

The control units used in each of the facilities was a Siemens Series 1500 PLC, an advanced control system that enables complex control tasks while ensuring high-level fail-safety. This way, it was possible to meet two of the customer’s requirements at once: the demand to use only latest-generation technology, and to ensure technical uniformity as well as long-term availability of replacement parts.

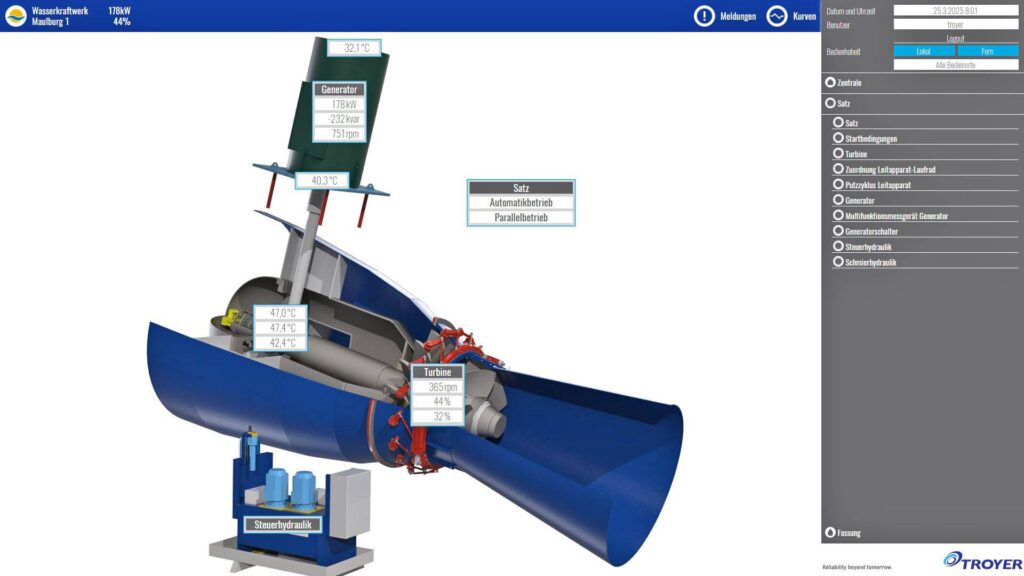

As Tobia Walpoth recalls, a typical example of the challenges that Troyer’s engineers were faced with was the Maulburg I facility. As the last one to be completed in 2024 it exhibited a lot of the basic problems affecting the group of facilities as a whole: “The forebay, the trash rack cleaning system and the machine unit were all fitted with control systems from different manufacturers. That’s three different control arrays for three key components. No wonder the communication between them didn’t really work as it should,” says TobiaWalpoth, adding that “We implemented a uniform system that brings all components together at a single point of control. For one thing, the different components can now be accessed remotely. And the turbine operation and forebays can also be adjusted as needed across the entire group of facilities. That’s state-of-the-art water power utilisation as it should be.”

Access via unified visualisation

This also applies to the visualisation solution. Acting as an interface between the process controls and human staff, visualisation is an all-important tool that today’s hydropower facilities couldn’t do without. For many years Troyer have been providing a special software for this purpose. It generates a well-designed graphic representation of all processes, simplifying the tasks of controlling and monitoring relevant operational parameters. “We’ve installed the new-generation visualisation software we launched some three years ago. It runs on a PC in a control cabinet, which communicates with the PLC via a data exchange connection. This means the visualisation tool is operated autonomously at each power station within the group. But what makes this system special is that it gives all visualisation-enabled touch panels and computers access to the central server via a web browser. This way, the entire system is always fully synchronised and up-to-date. For example, to add a new operating parameter you only have to set it up once to make it instantly available to all visualisation instances throughout the system. Admittedly that’s also a big plus for us as providers, as our software engineers have to implement changes only once. Previously they had to modify each touch panel individually to implement a change. Fortunately, that’s now a thing of the past,” says project leader Pirmin Schneider.

With the introduction of the new visualisation solution a new era has dawned for the power stations. “The visualisations show all the relevant readings and performance details, both the current ones and archived earlier ones. We now get all the sensor data in real time. Previously we had to count ourselves lucky to get even a few current readings now and then,” as Tim Schöne explains.

© Troyer

Full control via an overarching control system

A new, overarching control system turned out to provide a significant performance boost in terms of unification and optimisation. “An overarching control system wasn’t even part of our original plan. But once Troyer presented it to us, we knew that this was the way to go,” as Tim Schöne recalls. Technologically speaking, the solution provided by Pirmin Schneider’s team is a cloud-driven solution with a web-based open-source GUI. Operational data of the individual power stations are uploaded to the Cloud, from where they can be accessed for on-screen visualisation. The design of the overall control and automation system is based on an overview display. It provides a summary of all relevant operational data across all facilities within seconds. “On the visualisation panel we can instantly see if there is a problem at one of the facilities. The control desk provides remote access to the individual visualisation instances. This, in turn, gives the operator access to the operational processes at the individual power stations.

In addition to the six modernised facilities we also integrated the Hottingen and Mambach power stations – the ones that were equipped with Troyer systems around 10 years ago. Further facilities are expected to follow, as Schöne confirms. “We’re also planning to integrate all the existing facilities that are currently using third-party equipment into our new control solution.” As Tobia Walpoth points out, first steps to do so have already been taken. “We’ve installed gateways at most of the facilities to make them fit for the new control technology. It’s all well supported technically.”

© Troyer

Remote control ensures economic advantage

As far as Time Schöne and his team of engineers are concerned, having a wide range of new remote monitoring and control options available is one of the brightest highlights of the successful modernisation project. Aside from providing better, more fine-grained control options, the solution has also saved the team a lot of on-site work. “Now our operating staff can access the facilities conveniently from home. The power stations are completely remote controllable. Previously, you had to be on-site to adjust a control parameter. Lots of tasks that used to require manual intervention are now fully automated,” says Tim Schöne, adding that “With the new controls reducing the number of incidents, our costs have gone down quite a bit. And even in case an incident does occur, it can be resolved remotely. This saves us not just the costs for frequent on-call and weekend duty, but also the need to drive back and forth – after all, some of the facilities are up to a 60 kilometre drive away from the control room. What’s more, these time savings mean longer operating hours for our facilities, which helps to boost economic efficiency.”

© Troyer

Perfect coordination between components

In addition to lowering the number of incidents, the new control equipment has also allowed the operators to optimise the energy efficiency of the facilities. As Tobia Walpoth explains, “Today it’s state-of-the-art for the various parts of a power station, like the forebay and power house, to communicate with one another via data exchange. This way, they can be fine-tuned to ensure an optimum energy output. To make that possible we’ve installed fibre-optic connections between the more remote components, and Ethernet connections for shorter distances. With the new controls in place, we are able to implement optimisations to ensure longer operating times and resulting higher annual energy output.”

Another benefit, says Troyer’s expert technician and software engineer, is the modern sensor array that has been installed as part of the project. It provides more and higher-quality data, which can also be used for maintenance purposes. Translated into graphs and diagrams, the accurate readings enable precise, economically efficient maintenance planning.

Automation team demonstrates competence and flexibility

Using a special interface, Troyer’s stand-by automation team also has remote access to the control and automation system of naturenergie’s modified power stations to take action as needed. Especially when it comes to making minor adjustments or addressing unexpected error messages, the South Tyrolean team of experts are standing ready to react and respond promptly and accurately. “This arrangement has been working perfectly. A telephone call is usually all it takes to have the adjustment applied by the next day,” says Tim Schöne, paying Troyer’s team a compliment by adding, “We were highly impressed, not just with their quality of work but also with their speed and flexibility in getting things done. Especially when we needed some adjustment at short notice or when we needed some extra feature, they always responded in a friendly and professional manner. Our collaboration was highly successful – we really enjoyed working with them!”

A prolongation of the collaboration is already highly likely. That is because the control equipment in the two power stations operated by naturenergie on behalf of third-party providers are also scheduled for an upgrade in the not too distant future. And the other facilities that were excluded from this project are likely to require a similar control and automation upgrade in the coming years.