Industry professionals multiply power plant outputwith replacement construction in South Tyrol

In hydropower, tradition and modernity often go hand in hand. Operators in St. Johann in Ahrntal, South Tyrol, have reawakened a traditional site in the centre of the village with the installation of cutting edge hydropower technology to create their own state-of-the-art green energy plant. The plans compiled by the Bruneck planning office Studio G show how the old Schmied hydropower plant, that had previously only achieved a power output of 15 kW, was completely renovated to generate 340 kW and supply around 1.3 GWh of clean electricity per year. The site also underwent enormous improvements in terms of water ecology, and the new power plant has been in regular operation since August 2024.

© Studio G

Few valleys in South Tyrol can boast such an abundance of water as Ahrntal. No fewer than 38 smaller glacial formations in the surrounding three-thousand metre peaks ensure that Ahrntal and its side valleys have plenty of water flowing through them. Previously, this was channelled toward the fields for agriculture via above-ground free-flowing channels, a well-known system called the ‘Waale’.

Obviously. These resources were also used to power various trades, including mills, forges and sawmills. Since the last century, it has been used by numerous power stations to generate electricity. Modern small-scale hydroelectric power stations, particularly those built here in the last 20 years, show how water power potential in the Ahrntal Valley can be harnessed effectively using the very latest small power station technology.

© Brunner & Leiter

A history of blacksmithery

The old Schmied power station in the centre of St. Johann im Ahrntal was, until a few years ago, anything but modern. The original plant failed to meet the standards and requirements of modern hydropower applications, either in terms of technology or fish ecology. At a site with a long history, the old turbine merely delivered 15 kW of power – so action was required. “Utilisation of water power from the Ahr at the ‚Schmied‘ in St. Johann dates back to the 18th century. For many decades forge machinery was driven by belts and mechanical drives. In the 20th century the power of the Ahr was harnessed for electricity production via a turbine and generator. The blacksmith’s trade was practised by the ancestors of the current owners until the mid 20thcentury. Historically, it formed the economic basis that supported several generations,” explains Adolf Dengg (Dipl.-Ing.). As the Studio G engineering planner from Bruneck responsible for the new power station, Dengg is obviously familiar with every single detail of the plant.

© Studio G

More water – greater yield

A few years ago the current Schmied owners joined forces with several interested parties to form a company with the aim of continuing the tradition of hydropower at the site in an optimised form. To this end the newly founded Kraftwerk Schmied GmbH commissioned Studio G, a highly-reputed planning office in the region that has been very successful in the realisation of numerous hydropower projects in South Tyrol over recent decades. Key expectations placed on the replacement infrastructure were an increase in the volume of water processed, modernisation in terms of water ecology, and the use of state-of-the-art electromechanical components. Dengg added: “The flood protection structures were renewed and reinforced throughout the entire plant area.”

Construction process challenges

Construction work began at the beginning of September 2023. The extreme tightness of the space between the residential building and the riverbed meant the construction pit – which extended to around 4 metres below the stream bed – had to be sealed all the way around by way of jet grouting. This method, also known as soil compaction grouting, is a form of earth grouting used to create cement-soil composites in the ground. In-situ soil is mixed with a cement-containing binder suspension under high pressure.

Power plant planner Adolf Dengg explains: “Transverse and longitudinal sill implementation was realised in the stream bed during the period of low water-levels. The transverse sill was dimensioned to accommodate residual water allocation and the fish pass entrance.” In addition, the stream bed was separated from the site excavation via earth damming so that the concreting tasks for the intake, intake channel, underground powerhouse, transfer cabin and return channel, could all be carried out in a dry environment.

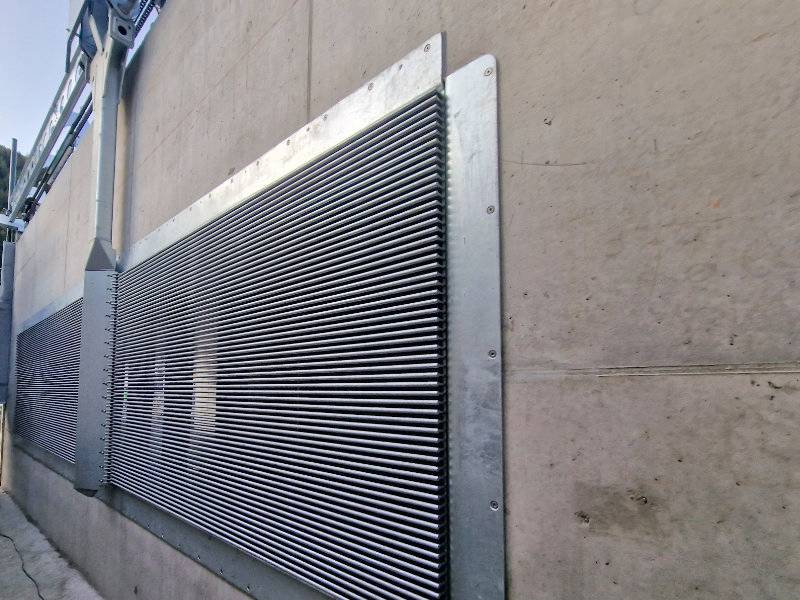

Safety with high-quality steel construction

A shut-off gate was installed upstream of the flushing channel at the catchment. At 9 metres wide, 2.5 metres high and made of concrete, safe closure was ensured under its own weight – even without electricity. The entire hydraulic steel construction of the water intake was implemented by the specialists at South Tyrol company Wild Metal, one of the best-known names in the industry. Wild Metal’s scope of services also included the inlet gate, which closes off the flushing channel positioned behind it. The upper part of the steel structure can be lowered once the trash rack cleaner has pushed the flotsam off the horizontal screen and downstream. Cleaning system is a hydraulically operated, fully automatic horizontal trash rack cleaner, and offers immense advantages – particularly fish-friendly power plant operation. Tight bar spacing and lower flow velocities on the horizontal rake reduce the hazards for fish in the Ahr significantly. An additional plus point for Wild Metal trash rack cleaners is that – right from the basic design stage – the South Tyrolean industry engineering specialists attach great importance to the easiest possible accessibility to spare and wear parts, and to components requiring maintenance. Thanks to their extremely robust design, Wild Metal‘s trash rack cleaners guarantee a long working life and ensure a high degree of operational reliability, even under the most adverse operating conditions.

Power generation in immersion mode

The water is channelled through an inlet 4.5 m wide at the side intake of the new water catchment. It drops away over the last few metres down to the machine set consisting of a double-regulated Kaplan tube turbine and a directly-coupled submersible generator. “The machine set was also installed with an inclined axis in order to direct the water flow onto the blades of the Kaplan turbine as effectively and with as few deflections as possible. The submersible generator protrudes into the headwater and is thus water-cooled,” explains Adolf Dengg. Here, the benefits of a Kaplan tube turbine are that the inlet shaft, turbine and draft tube are arranged without any change in direction, meaning this type of turbine is very efficient – and that the design is extremely compact. Designed, manufactured and delivered by Sora – the South Tyrolean turbine specialists – for a volume capacity of 13 m3/s, the modern turbine, accommodates a net head of 3.20 m at Qmax. At maximum the Kaplan turbine generates an output of 340 kW – truly a quantum leap from the 15 kW achieved by the old turbine.

This reference project has had a significant external impact for the turbine manufacturers at Sora, having enabled the company to prove its capacity to deliver high-performance turbines for the low-pressure sector. Similarly, Sora has enjoyed success in the medium-pressure range, having recently added the diagonal turbine to its product portfolio and having seen it put into operational use.

© Studio G

Noise emission-free hydropower plant

Following the further course of the discharged headrace water, the large outlet gate with dam beam inspection slots is located after the concreted-in steel suction pipe connected directly to the turbine. The return channel then rises diagonally to the 17-metre outlet sill. The control room is located above the turbine, and to facilitate easy access the transfer cabin had to be positioned to the side – as specified by the local grid operator. The small rooms opposite are for the transformer and medium voltage power management. As the system was built directly onto the neighbouring residential building in this area, this section and the first few metres of the return duct were fitted with external sound insulation. This achieved the desired effect. Vibrations can no longer be felt in the existing building during operation, nor can any transmission of structurally transmitted noise be detected.

© Studio G

Average annual power output of 1.3 GWh

In just less than a year the operators of the new Ahrn power plant in St. Johann succeeded in replacing a small, outdated and inefficient power plant with a modern, high-performance set-up. The new infrastructure is state-of-the-art in every respect. After a short trial phase in July last year, the new Schmied power plant went into regular operation at the end of August 2024. The new hydropower plant is green, in keeping with the generation-spanning tradition of hydropower utilisation at the location, and is one of numerous modern small hydropower plants along the water-rich Ahrntal valley. Now, the new low-pressure plant can supply an annual average of around 1.3 GWh of clean electricity, contributing significantly to the local energy supply. This project also represents an important building block in the South Tyrolean energy strategy, according to which around 100 % of South Tyrol‘s electricity requirements are to be covered by renewable energy sources by 2050.