DIVE and Natel are raising the bar for safe fish passage in small hydropower

Bild: © Natel

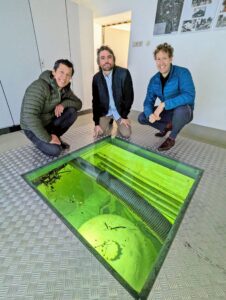

Trusted hydro turbine manufacturer and developer DIVE Turbinen GmbH & Co. KG from Germany is collaborating with sustainable hydropower innovator Natel from the USA to accelerate deployment of FishSafe™ hydropower turbines around the globe. In the race to combat climate change, maintaining and expanding the world’s hydropower fleet has never been more critical. Hydropower is a tested and reliable renewable energy source, but its traditional implementations may come at a cost to river ecosystems, particularly in hindering the safe up- and downstream passage of fish. Many strategies for upstream fish passage exist, but downstream through-turbine passage is of special interest and a true challenge for existing turbines on the market.

© Natel

A new collaboration between DIVE and Natel builds on a timely understanding that efforts to combat climate change must also address biodiversity loss. This collaboration will see the integration of the DIVE-Turbine powertrain with Natel’s FishSafe™️ runner design. DIVE has a proven track record as a turbine manufacturer, having installed more than 65 compact, efficient, and reliable turbines at sites across the globe since 2006. With a global installed capacity of 32 MW producing around 160 GWh/a clean energy per year and saving the equivalent of 54,000 tonnes of CO2 emissions per year in comparison to a modern gas-fired power plant. DIVE turbines use highly efficient direct drive permanent magnet generators in a submersible package that has allowed small hydropower plants to operate with exceptionally low cost and risks. DIVE is committed to advancing fish-friendly hydropower. DIVE-Turbines utilise a runner with fixed blades and speed variation, which has already a lower fish mortality than a Kaplan turbine with variable pitch blades and a fixed speed.

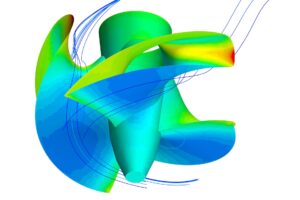

By collaborating with Natel, DIVE is working to further increase the fish-friendliness of their turbines. Natel has pioneered unique methods for turbine runner design focused on fish safety in hydropower applications. Through rigorous testing and refinement, Natel has achieved fish passage survival rates of 98-100 % across multiple fish species and life stages, at high blade speeds. Using Natel’s runner designs, the two companies aim to achieve fish safety at all operating conditions (part-load through full-load) without the need for a fine fish exclusion screen.

© Natel

Joining forces for maintenance-free FishSafe™ hydropower

The DIVE-Natel Turbine is a high-performance, maintenance-free turbine that is safe for fish passage, combining the strengths of each company. These turbines are available for sites with up to 40 m of head and in unit sizes up to 4.50 MW. A direct-drive, vertical axis, submersible turbine, the DIVE-Natel Turbine is flood secure and is available pretested and preassembled, minimising work on site. Based on the unique DIVE sealing and DIVE bearing the turbine-generator-unit is also permanent runaway capable and largely maintenance-free, requiring only a 5-year oil change and 20-year bearing change. The DIVE-Natel Turbine features Natel’s patented, thick, forward-swept blade design, which can eliminate the need for fine screens to protect fish from turbine injury. Without screens, more flow can be used for generation and costs associated with installing and maintaining screening are reduced.

© Dive

A once-in-a-generation opportunity

The global hydropower fleet faces an urgent need for modernisation, and the DIVE- Natel Turbine meets that need while ad- ditionally helping to bring those sites into compliance with new regulations for fish survival. “We’re excited to offer the DIVE-Natel Turbine, an efficient, submersible hydroelectric turbine for low and medium head sites that combines high performance and reliability with safe downstream fish passage,” said Christian Winkler, Sales and Product Manager at DIVE. “By incorporating Natel’s FishSafe™ runner design into our low-maintenance DIVE-Turbine, we can upgrade an existing plant’s efficiency and environmental performance simultaneously.” Like the standard DIVE-Turbine, DIVE- Natel Turbines generally have fixed runner blades.

© Dive

If needed at variable flow and head conditions, the speed of the DIVE-Natel Turbine can be varied instead of varying the runner blades’ pitch. The speed variation reduces the speed of the turbine as the flow decreases. This achieves a hydraulically similar effect to the mechanical adjustment of the runner blades in Kaplan turbines with comparable efficiencies. The use of the Natel FishSafe™ runner with the DIVE-Turbine enables higher operating speeds while still ensuring safe fish passage. The DIVE-Natel Turbine enables safe down- stream fish passage while also simplifying operations & maintenance as well as minimising the flood risk for the Turbine-Generator-Unit. With reduced mechanical complexity, the DIVE-Natel Turbine can achieve equivalent annual production to a Kaplan turbine in typical applications. Most importantly, DIVE-Natel Turbines are both highly efficient and highly reliable, resulting in reduced downtime and improved overall power production.

© Natel

High fish safety, low CAPEX & OPEX

Submersible DIVE-Turbines, known for their direct-drive generator and unique seal and bearing design, minimise OPEX due to virtually maintenance-free operation and robustness. Their compactness and customised design allow for easy integration into existing power plants, minimising CAPEX.Through our collaboration with DIVE, we’re joining DIVE’s expertise as a turbine manufacturer with Natel’s breakthrough FishSafe™ technology” said Gia Schneider, CEO and co-founder of Natel. “Fish are vital to the global economy, food supply, and ecosystem function and it is essential that we plan for a future that sustains fish populations while also enabling us to modernise the existing hydro fleet and advance the transition to a reliable, carbon-free grid.” By combining Natel’s proven FishSafe™ runner designs with DIVE’s compact, efficient, and reliable turbines and demonstrated manufacturing experience, the two companies have pioneered a solution poised to redefine the standards of fish-friendly hydropower for small hydropower plants.