Adont high-pressure hydropower plant in Grisons now generates energy from high Alpine river

In October 2021, just 1½ years after the ground-breaking ceremony in the Swiss village of Surses in Grisons, the small-scale Adont hydroelectric power plant went online. The plant operators EWZ had chosen to build a new high-pressure plant to generate electricity and take advantage of the immense difference in altitude (620 m) between the catchment basin and the operations centre. Installation of the 4.2 kilometre penstock posed considerable construction and logistics challenges, since routing had to avoid a whole series of protected areas. At 1,720 m above sea level, the reservoir had to be equipped with the generally self-cleaning GRIZZLY Coanda system by Wild Metal, the South Tyrol hydraulic steel construction experts. A 4-jet Pelton turbine in the power station headquarters was also produced by South Tyrolians, Troyer AG – a guarantee for maximum efficiency. EWZ forecasts this latest small-scale hydropower plant will reach an annual green-power output of around 10.2 GWh.

The realisation of the first hydropower plant on the River Adont, which joins the River Julia in the village of Surses, began with a study of existing power potential carried out in 2009 by the City of Zurich electricity authority (EWZ). Martin Klauenbösch, EWZ’s project manager, explains: “Once subsidisation for hydropower was increased in Switzerland from 2009 onward, EWZ seized the opportunity to identify areas of unexploited potential – particularly with villages in regions in which EWZ was already licensed to run hydroelectric infrastructure. Of the many studies of potential, the construction of a small-scale water power station on the River Adont was clearly the most promising.” Klauenbösch also remarked how long and complicated dealings with the authorities had been on the road to licensing. One major obstacle was posed by the numerous protected natural areas along the route of the penstock. “The investigation of possible environmental effects took around 3 years. It was essential for us to involve all of the environmental associations and authorities, and several of the (at that time) independent towns and land owners. This proved to be the right approach as we ultimately found a satisfactory solution for all parties involved.”

CONSTRUCTION COINCIDES WITH PANDEMIC

Although the building permit was issued in 2017, it still took several years before the power plant went online. However, once the KEV green electricity tariff subsidy was agreed – rewarding customers who contributed energy to the grid – the project became a financially stable proposition. Building activity finally commenced at the beginning of 2020, just as the Corona pandemic began to take a hold. According to Klauenbösch: “Despite initial insecurity about the situation, we decided to implement the project subject to safety and hygiene guidelines. In view of the current shortage of building materials on the market, and the price spikes triggered across the entire building sector, we’re lucky we didn’t decide to build the plant later.” The above and below-surface construction work, and the installation of the penstock, was carried out by three companies based in the region. “We were fortunate renowned companies from the construction and hydropower sectors submitted the best offers during the call for bids. It was good to see local construction companies receiving contracts and generating profit in the region” Klauenbösch remarked.

TOP PRIORITY FOR NATURE PRESERVATION

When building began in April 2020, the first step was to move the control centre further uphill from the area known as Savognin. The routing and installation of around 4.2 km of penstock began at the end of May, work on the reservoir infrastructure at the start of July. Klauenbösch points out that the River Adont cuts deeply into the Alpine terrain at some points, making it extremely inaccessible: “The site is unusually accessible for an alpine water catchment, and even has its own access road. Nevertheless, a transport helicopter was used in some sections to fly out felled trees to cause as little ecological influence as possible. Routing for the penstock had to meet multiple criteria. The land around the project site is composed of fenland, dry grassland and other protected biotopes around which the penstock had to be navigated.” In addition, geological measurements were taken around the location of the water catchment over a period of roughly 10 years. The minimal earth movements registered necessitated a particular structural approach to the building of the water catchment. To protect the structure of the catchment basin in the case of the earth moving, the two limbs of the L-shaped construction were built separately from one another. The longer limb in which the sand collector is situated, and shorter limb angled at 90°, where water intake occurs, are connected to each other via two pipes. On the ends of each of the DN600 pipes are joints to allow earth movement compensation.

GRIZZLY PROTECTS THE WATER CATCHMENT

Agreeable weather conditions, even at 1,723 metres above sea level, allowed all of the concrete elements for the reservoir to be completed within the first year. The patented, mostly self-cleaning GRIZZLY Coanda system, is made by the hydraulic steel construction specialists at Wild Metal in South Tyrol, and was installed in 2020. The undisputed quality of this system has now been installed and used throughout the Central Alps over 500 times. The eponymous Coanda principle combines with the shearing effect to ensure water is redirected automatically. Similarly, the narrowness (0.6 mm) of the gaps prevents organic and inorganic solids from entering the basin. A coarse rake mounted further up protects the fine rake from rocks and branches. Up to 600 l/s pass through the GRIZZLY every second. They are then guided on to the two-chamber desander basin where the Adont’s fine sediments are filtered out before the purified works water is guided down into the penstock. Wild Metal’s scope of delivery also included a whole series of hydraulic gates, stoplogs, hydraulic power units, piping and the emergency closing valve. Environmental flow is released via an underwater pipe. In the colder months the water has to be drawn from a special winter intake facility at a prescribed constant minimum flow volume of 90 l/s. In the summer months the fixed minimum is raised to 105 l/s, plus 1/8 of the respective influx.

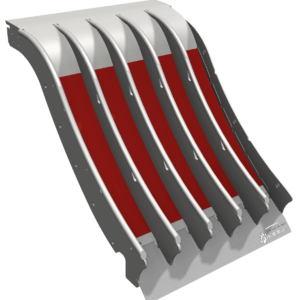

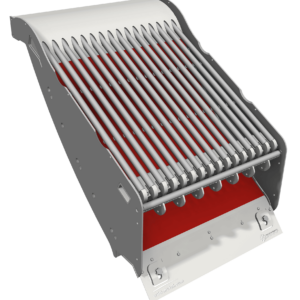

THREE BREEDS OF GRIZZLY

Since operational requirements and conditions on site at the location of a catchment basin vary considerably, Wild Metal has developed three basic versions of its GRIZZLY system. Modular construction allows each GRIZZLY to be easily adapted to the size of the respective water catchment. The three versions are the GRIZZLY Power Protec – the module also in operation at the water catchment at the Adont power plant; the GRIZZLY Power Titan, and the GRIZZLY Power Optimus. Wild Metal is able to meet most of the basic requirements of all projects worldwide with these three versions. The GRIZZLY Power Protec is particularly well-suited to powerful Alpine rivers carrying large volumes of debris. The profile bars on the upper part of the structure are usually spaced between 30 to 50 mm apart to protect the fine screen below from bulkier elements. The special arrangement of the bars ensures very few stones or pieces of driftwood are caught in the rake. Fish and other creatures inhabiting the water, if no larger than 0.2 to 2 mm, can easily pass through the fine rake with the flowing water; as can leaves, pine needles and smaller water-borne debris. Resultantly, maintenance work and manual cleaning of the catchment basin is reduced to a minimum. Wild Metal developed the GRIZZLY Power Titan for bodies of water with large fish populations, large volumes of fallen foliage, but only small volumes of rocks. The Titan is typically installed at the outlet of a lake. The fine grille of this version of the GRIZZLY is protected by robust, rounded steel ribs. Tree trunks, branches and roots glide over the Titan easily with the motion of the water. The final member of the GRIZZLY system trio is the Optimus, designed to work without the larger protective rakes above. Optimus can be installed wherever a catchment basin is already protected by a larger rake. This mostly applies to catchment basins with water release outlets along the side, but is also found in water treatment plants, fish breeding farms, water intakes for industrial cooling systems, snowmaking or irrigation purposes. Depending on the type of GRIZZLY required, Wild Metal can provide Coanda screen systems with slot gap sizes between 0.2 mm and 2.0 mm, and customers can choose from a variety of wedge wire profiles.

ZIG-ZAG PENSTOCK

At approximately 200m below the catchment basin the upper section of the penstock, built with DN600 piping, crosses an above-ground pipe bridge. A 35-m rectangular-cross-section truss bridge was built to span the water. For roughly the first 1000 metres the penstock routing runs along a relatively shallow gradient, after which the terrain of the penstock drops away dramatically on its way down to the control centre. The final 1,000 metres of the penstock are built using narrower DN500 sections. “Routing the penstock was one of the major challenges of the project and required multiple changes of direction. The also explains why it wasn’t possible to build for a constant gradient. Instead, it was necessary to install a highest and lowest point, and to include an air intake and release valve” Klauenbösch told us. The sheer physical stress on a pipeline in the Alps meant it was necessary to construct the entire pipeline using robust ductile cast iron pipes, using sleeve connectors resistant to shearing and crushing. Breaking through the mountainside enabled the penstock to be routed under the local canton road. Around two thirds of the entire pipeline had already been installed by the end of November 2020 as the first snowfall ended the construction season.

4-JET POWERHOUSE

Electromechanical expansion of the control centre began in May 2021. All of the equipment was provided by the hydropower allrounders Troyer AG from South Tyrol. The centrepiece of the Adont hydroelectric plant is a vertical-axis 4-jet Pelton turbine. The hydraulically-regulated Pelton jets within the housing guarantee excellent degrees of effectiveness across a broad operating spectrum. Operating at full capacity the plant processes 600 l/s from a 620.80-m gross head. Being designed for this capacity, the turbine achieves a constant standard maximum power output of 2,950kW. The physical forces applied by 62 bars of pressure acting on components in contact with the water meant components like the runner and turbine ring pipe had to be built to be extremely robust. The milled monoblock stainless steel runner is directly connected to a turbine shaft driving a Hitzinger synchronous generator rotating at 1,000 rpm. To ensure the generator operates at ideal temperatures it was given special water-cooled housing, drawing water from an underwater heat exchange unit. The generator produces 6,300 volts and is set up for a nominal apparent power output of 4,000 kVA. The generator shaft transmits the power produced to the machine transformer hooked up to the medium-voltage switch system. Troyer’s scope of delivery also encompassed the secondary technology at the control centre, including the hydraulic engines, plant power supply transformer and the emergency power supply batteries. Hooking up to the public power grid was the least challenging and expensive activity of the entire project. The energy is conducted from the air-cooled 11kV transformer into the grid via an existing feed-in point around 15 metres away. Martin Klauenbösch pointed out that superior-quality equipment was a general priority for EWZ: “EWZ comes from the large-scale hydroelectric power sector in which higher quality and safety standards are basic expectations, so it’s obvious quality equipment is chosen for smaller projects, too. Of course, high standards also apply to the plant software and automation solutions.” Troyer and EWZ collaborated on the programming of the power plant control technology required for fully-automated operation of the infrastructure. The plant is monitored and regulated at the EWZ control centre in Sils, 15 km away.

10.2 GWH OF GREEN ELECTRICITY EVERY YEAR

The turbine was finally ready to go online last October around 1½ years after construction activity commenced. “Final commissioning was a special moment. After such a long preparation period, requiring so much patience, the actual building phase progressed very rapidly. And suddenly the machine was in operation. This success was down to the hard work of all the project staff involved at EWZ, and the cooperation with all the external businesses”, summarised Martin Klauenbösch. After a two-week trial period in the autumn the plant was taken off-grid again in order to complete all remaining tasks. With the snowmelt season imminent Klauenbösch is optimistic the power plant will soon be working at full capacity. In total EWZ invested around CHF 15 million in the project. An average yearly output of around 10.2 GWh of green electricity is expected to cover the annual requirements of approximately 4,300 average households, so it’s easy to see why this project has been such a resounding success.