New small-scale hydropower plant in Valle d‘Aosta goes online in spring 2025

Bild: © Alessandro Mosso

A brand-new small-scale hydropower plant has been generating clean electricity on the Saint Barthélemy stream in Aosta Valley, Italy, since spring 2025. The diversion power plant offers a generation capacity of around 3.5 GWh, and the construction team succeeded in reconciling technical power generation requirements with aquatic ecology concerns. The machine building at the plant was constructed completely underground to preserve the landscape, and houses a vertical-axis Pelton turbine with a bottleneck capacity of just under 400 kW. A ‘Grizzly’ Coanda was installed at the water intake – a tried and trusted system built by the South Tyrolean industry specialists at Wild Metal. A vertical slot pass was fitted to ensure safe and smooth passage for fish. The patented system draws in water at a rate of maximum 1,000 l/s and ensures optimum sediment filtration.

© Alessandro Mosso

The northern Italian municipality of Nus in Aosta Valley has a population of just under 3,000, and is particularly well-known among wine connoisseurs for the local Vien de Nus grape variety. The large number of hydropower plants in the valley reflects the fact the alpine topography of the idyllic region provides ideal conditions for the water-driven generation of electricity. Located on the Saint Barthélemy mountain stream, it’s one of the most recently-built small hydropower plants in the Aosta Valley. The project, implemented by the power plant company Soc. Idroelettrica St Barth Alto srl., was completed in spring 2025.

Combined hydropower plant and irrigation system

Ing. Alessandro Mosso, together with Blu Energie Srl, was responsible for general project planning, and explains that the initial construction concept for the new power plant had been drafted almost 20 years ago: “The first licence application for the project was submitted in 2007. Numerous revisions and optimisations were necessary over the years to ensure compliance with legal regulations and enhance the plant’s energy efficiency. The existing irrigation infrastructure for agricultural land in the project area had to be incorporated into the functional concept of the hydropower plant to minimise the environmental impact of the project and maximise the hydraulic efficiency of the power plant.” The planner explained how power plant construction contributed to optimisation of the agricultural irrigation system, and thereby to achievement of regional sustainability goals. As regards to the project planning phase, Mosso told of how the approval process had been complex and had lasted more than a decade, having also included several project reviews, hydraulic and ecological impact investigations and environmental impact assessments. Ultimately, the solution agreed met both structural and ecological requirements.

© Alessandro Mosso

Construction commences in the summer of 2022

The project implementation phase finally started in July 2022. The altitude of the overall project site was between around 1,480m and 1,650m above sea level, meaning primary work had to be carried out between the spring and autumn months. Due to the risk of avalanches, construction work had to be interrupted during the winter months. According to Alessandro Mosso, the unstable geological conditions posed a major challenge for construction. As a result of the conditions the contractors were required to carry out reinforcement measures on the plant structures and the penstock. The latter is 1,622 metre long and, in sections, navigates very steep terrain, hence needed to be reinforced with concrete anchor points. The power descent is made entirely of robust DN800 steel pipes that guide the water as it drops around 160 metres. Furthermore, a fibre optic cable was installed along with the penstock to facilitate digital communication between the water intake technical systems and the power station control centre. In addition to the penstock for the hydropower plant, a connecting pipe was also laid to feed the agricultural irrigation system. At approximately 950 m long the pipeline also consists of steel pipes, this time DN150-dimensioned conduits.

© Alessandro Mosso

Innovative water collection system with a self-cleaning function

At the water intake the project operators installed the innovative ‘Grizzly’ Coanda system, built by the South Tyrolean hydraulic steel construction experts at Wild Metal GmbH, where headrace water is diverted. Essentially it’s a virtually self-cleaning patented protective screen system that has proven its practical suitability hundreds of times across the Alps. Water passes through fine screen gaps of just 0,6 mm. The eponymous Coanda effect automatically flushes flotsam and debris from the screen surface. Positioned above the fine screen, reliable protection is provided from coarse floating debris like branches and rocks by a hot-dip-galvanised steel grid. Once the headrace water has been discharged through the Coanda system, it enters a desanding basin in which fine sediments from the headrace water settle slowly before the water flows into the penstock. As well as the ‘Grizzly’, Wild Metal GmbH also supplied the rest of the hydraulic steelwork equipment for the weir system. This included the desander basin flushing flap, various shut-off and regulating devices, and the fully automatic hydraulic control unit for the gates. Ecological waterway continuity was guaranteed by a vertical slot pass built to guide the fish from the tailwater – up past the weir system to the headwater.

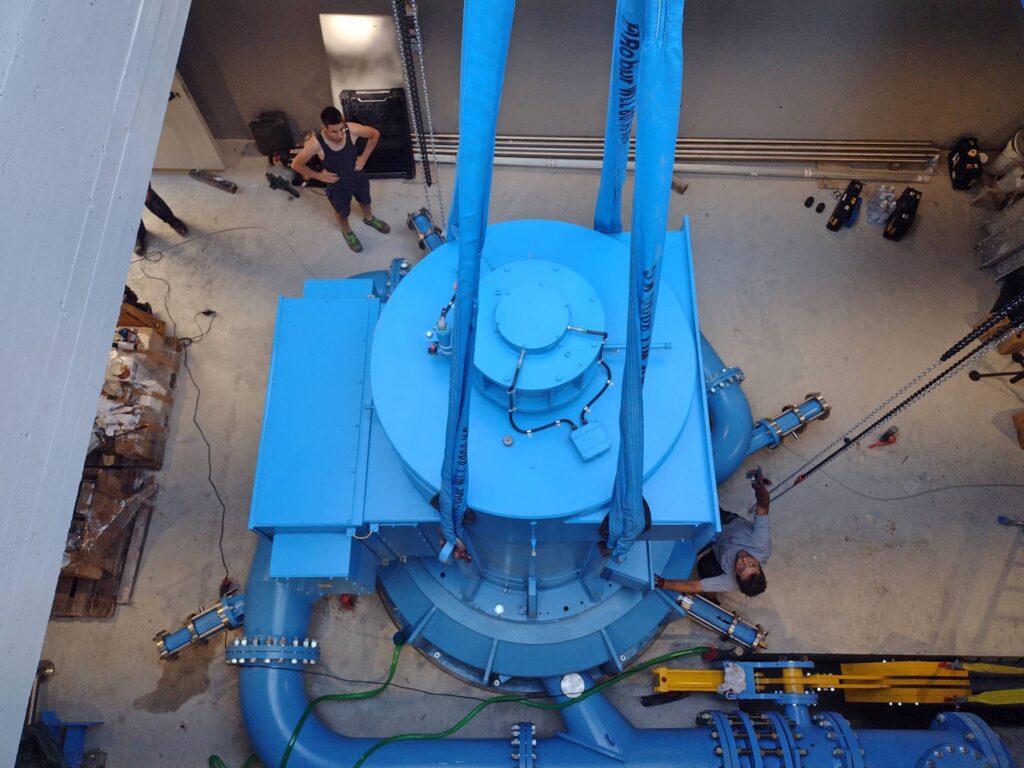

Powerful underground machine set

Visual impact on the landscape was minimised by constructing the turbine machine building completely underground. The centrepiece of the well-hidden plant control centre is a 4-nozzle vertical-axis Pelton turbine that drives a generator directly coupled to the runner. The machine set was supplied by Tamanini Hydro The turbine generates 398kW of maximum power at full water supply from an expansion water volume of 1,000 l/s and a net head of 159.11m. The multi-nozzle design enables the machine to operate effectively across a wide range of inflow volumes – and is highly efficient, even when inflow is greatly reduced. The machine set is completed by a 3-phase 1,500 kVA nominal apparent power synchronous generator. The 3-phase air-cooled generator was manufactured by Marelli Motori and was designed for an operating voltage of 3,000 V. The entire electrical and control infrastructure for the powerhouse was also supplied by Tamanini Hydro. Electricity production at the plant is a fully-automated state-of-the-art arrangement, which can be monitored and operated remotely around the clock using a secure online connection. The plant control set-up includes an intuitive visualisation system that provides a clear and simple overview of all the most important information pertaining to the current status of the power plant.

Feeding into the grid since spring 2025

In spring 2025, following completion of construction work, the new Saint Barthélemy small hydropower plant finally produced its first load of green electricity – which was fed onto the public grid via a newly installed approximately 3.5-kilometre underground cable. The project’s general planner, Alessandro Mosso, was absolutely satisfied with the final result: “Initial tests have already shown that the new electromechanical equipment is highly efficient. I am sure the power plant is going to give the operators a lot of pleasure in years to come.” The plant in Aosta Valley was built and completed in exemplary fashion, and in an average year it is expected to generate around 3.5 GWh of green electricity.