Small-scale hydropower station develops Styrian water body for eco power production

Bild: © Ernst Hackenberg

It was in September 2022 when a small-scale hydropower station in the Styrian municipality of St. Kathrein am Offenegg near Graz, Austria, went online to supply its first clean energy. The project was implemented by Hydro Energy Weizbach GmbH, who wanted to realise the full hydroelectric potential of the local water body for the production of clean energy. Up to 80 litres per second are collected and piped to the power house, utilising a net head of around 210m. Measuring 3,145m in length, the DN350 penstock consists of 50% PVC pipes and 50% ductile cast-iron pipework, both provided by Upper Austrian-based Geotrade Tiefbauprodukte GmbH. Inside the power house, a horizontally aligned 2-jet Pelton turbine works in combination with a directly coupled synchronous generator to ensure maximum efficiency. Despite the Corona pandemic and the challenging conditions caused by it, the engineers were able to complete the project successfully within about one and a half years.

First plans for setting up a small-scale hydropower station on the Weizbach rivulet in the small community of St. Kathrein am Offenegg were drawn up in 2015. It was only a year later that the project received the required environmental and official authorisation. Hydro Energy Weizbach GmbH was founded to manage the legal framework. However, the project – although given the official green light – remained on hold for several years. When it was finally completed in the summer of 2022, it was taken over by property developer Hartwig Warmuth. Besides his property development activities, the new owner is also an avid promoter of renewable energies. His photovoltaic facilities are installed throughout Carinthia and achieve a total output of around 2,500 kWh. In addition, Warmuth now operates two small-scale hydropower stations, including the new Weizbach facility.

© Ernst Hackenberg

OPTIMISING THE PROJECT

“Project optimisation work was kicked off in late 2020. This included both the water intake and the power house, and a realignment of the penstock. In 2021 it was time to go ahead with the actual construction,” explains Ernst Hackenberg, the project’s planner who is responsible for its final implementation. “The installation of the penstock,” he adds, “was done in close cooperation with the Styrian road administration. This was essential, as there was about a kilometre and a half of country road being built right along the power descent. Although this delayed things somewhat, it absolutely made sense from a logistic point of view.”

The new water intake was fitted with a hydraulically operated weir baffle, the inflow point being equipped with a horizontal protective screen with a clear bar spacing of 10 mm. The floating debris caught by the screen is transported to the weir baffle, where it is either removed manually or flushed out into the tailwater by lowering the sluice gate. Once it has passed the protective screen, the motive water is collected in a sand trap to let the finely grained sediments settle. The collected sediments are then discharged into the residual water stream via a flushing gate, which is controlled automatically by two sediment sensors in the sand trap. A near-natural pool pass at the weir gate ensures the required ecological compatibility of the water passage.

A PENSTOCK COMPOSED FROM PVC AND DUCTILE CAST IRON

The size DN350 penstock that connects the water intake to the power house has a total length of 3,145m. Two different pipe systems were used in its construction: “The upper section consists of PVC pipes with a PN16 pressure rating. The lower half is made from cast iron pipes to withstand the higher pressure conditions,” as Hackenberg explains. All basic materials, including the elbows and special cast parts were provided by Upper Austrian distributor Geotrade Tiefbauprodukte GmbH. The upper section is based on System TOM® PVC-O by Spanish-based provider Molecor. The pipes are made of highly durable PVC, the result of a special manufacturing process. This provides high levels of resistance against impact, high-pressure pulses and environmental effects to ensure a long lifecycle. Used in high and medium-pressure applications and drinking water facilities all over the world, the system is favoured for its low weight and superior value for money. The penstock’s mid-point marks the transition to the ductile cast-iron pipes for the lower section. They are from Geotrade’s GEOCAST product line, which provides diameter sizes up to DN1000. Known especially for their durability, the pipes easily withstand the higher pressures. A cement mortar coating makes their inner surface extra smooth to ensure optimum flow conditions and protection against corrosive effects. Additional qualities include a high level of static stability under load, resistance to fracture as well as longitudinally stable joints which, depending on their dimension, allow the pipe ends to bend by up to 5 degrees inside the coupling sleeves. Except for a traverse in the form of a pipe bridge across the rivulet, the entire power decent is routed underground. A data cable laid along the penstock provides a digital link with the water intake.

© Ernst Hackenberg

TURBINE FOR WIDE RANGE OF OPERATING CONDITIONS

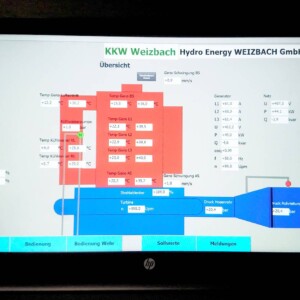

Inside the power house advanced hydropower technology ensures efficient power generation. The core of the facility is a Pelton turbine with two electrically controlled nozzles. Designed for a flow rate of 80l/s and a gross head of 210m, the machine has a bottleneck capacity of 140kW under full load. The twin-nozzle design ensures efficient operation within a wide partial-load spectrum at times when there is less water available. Although the original plans had called for an air-cooled generator, the engineers eventually opted for a less noisy water-cooled machine to meet the demands of local residents. The synchronous generator was manufactured by German-based EME Elektromaschinenbau Ettligen GmbH. The high-speed engine is coupled to the rotor and, like the turbine, runs at a rotational speed of 1,500rpm. It is designed for a voltage of 400V or rated apparent power of 150kVA (H-B). A modern control unit provides fully automated control of the entire facility, including a wide range of remote control options, thanks to a secured on-line control connection. Using an underground power line, the energy generated by the facility is fed into the public grid, which is operated by Energie Steiermark, via a transformer station located around 70 m away from the power house.

ON THE GRID SINCE AUTUMN 2022

About a year and a half after the official ground-breaking ceremony, the Weizbach hydropower station came oline in September 2022. “Despite the challenging circumstances surrounding the Corona pandemic we were finally able to bring the project to a very successful completion. Due to the dry weather during the first year of operation, the facility hasn’t been able to make full use of its design capacity so far. That said, it has been running without interruptions since autumn 2022,” says Hackenberg. In a normal year, the new power facility on the Weizbach is expected to generate around 600,000 kWh of green energy.