Symbiosis between Obervellach II traction power plant and Kaponigbach small hydroelectric power station

Bild: © GUGLER

Construction of the new Obervellach II traction power plant in Mölltal Valley, Carinthia is a role-model green electricity project now nearing completion. Realisation of the plant, devised to enable the Austrian Federal Railways (ÖBB) to produce around 125 GWh of electricity per year, generated considerable construction costs. The contract included construction of a headrace approximately 4 kilometres long, installation of a storage tunnel with a capacity of 60,000 m³ and the building of three new water intakes on the Mallnitzbach, Dösenbach and Kaponigbach rivers. A new small hydropower plant was also built on Kaponigbach River and equipped by GUGLER Water Turbines GmbH with a complete electromechanical package. The Austrian industry experts provided a 1.6 MW 3-nozzle Pelton turbine to ensure the hydro-energetic potential of the Kaponigbach was used to produce green electricity before being turbined a second time at the traction power plant.

© GUGLER

The ÖBB has been producing environmentally-friendly energy with hydropower for more than 100 years. In the mountainous provinces of Vorarlberg, Tyrol, Salzburg and Carinthia, the first hydroelectric power plants were built for railways as early as the 1920s. Nowadays in Austria the annual consumption of electricity by a railway at 16.7 Hz is around 2,000 GWh. Approximately a third of this demand is generated by the ÖBB‘s own hydroelectric power plants. The remainder is supplied by partner hydropower plants, drawn from the public grid, and converted to traction current frequency by the ÖBB with frequency converters.

© GUGLER

Railway hydropower

In Carinthia, completed in 1929 after seven years of construction, Obervellach I hydroelectric power station was an important cornerstone of the railway power supply in southern Austria. The power plant was expanded in the 1940s as electrification of the rail network progressed, integrating a second penstock and a third set of machines. The addition of the Kaponigbach further expanded the power infrastructure in 1947 and 1948. In fact, the smaller Lassach power plant, whose headrace water was later used by the Obervellach I power plant, supplied the Tauern railway tunnel construction site with electricity as early as 1910. After more than 100 and 90 years of operation respectively, ÖBB looked to modernise the two power plants comprehensively as they had reached the end of their technical service lives. The Carinthian provincial government gave approval for the project in 2015, and the main construction phase for the new Obervellach II power plant to replace the two old railway power plants – Obervellach I and Lassach – commenced in 2020.

Comprehensive modernisation

The complete refurbishment will increase the plant‘s control energy capacity by around 35 per cent. In a standard year, Obervellach II is expected to generate around 125 GWh of green electricity, the equivalent of the power required for around 30,000 journeys on the Railjet from Villach to Vienna. Electricity is generated by two Pelton machine sets mounted in the new powerhouse. Together they will produce a bottleneck output of around 37 MW, a total expansion water volume of 9 m³/s and a gross head of 488 metres. Works water for the new ÖBB hydropower plant is sourced via three separate water intakes on the Mallnitzbach, Dösenbach and Kaponigbach rivers. Catchments on the Mallnitzbach and the Dösenbach feed headrace water along a tunnel almost 4 kilometres in length with a diameter of approximately 3 m to a storage tunnel with a capacity of 60,000 m³. The third water intake on Kaponigbach River first guides the water to the newly-built small hydropower plant before the headrace water is then channelled into a storage tunnel to serve the traction power plant. The final section of the headrace begins at the storage tunnel machine room, and leads to the powerhouse in Obervellach via a 1.8-metre diameter penstock.

© ÖBB/ÖBA

Industry experts prove calculation skills

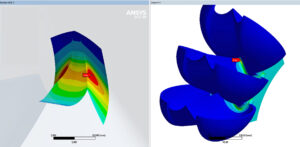

GUGLER Water Turbines GmbH is an internationally renowned company and was responsible for providing the hydroelectric equipment at the Kaponingbach power station, demonstrating its expertise to the ÖBB for the first time within the framework of this project. The scope of delivery for the Upper Austrian-based hydroelectric all-rounders included a 3-nozzle Pelton turbine with a directly coupled synchronous generator, a ball valve, a hydraulic unit and a bypass system with shut-off valves, the full range of electrical infrastructure – and the power plant control system. “The machine building was integrated into a mountainside at around 1,100 metres above sea level. This location posed a number of logistical challenges as equipment could only be transported along a narrow access road. The horizontal-axis-design 3-nozzle Pelton turbine was an ideal solution for the power station on Kaponigbach River, in terms of its hydraulic design and the space available in the powerhouse. The limited space in the machine building was also taken into account in its compact design. The hydraulically-controlled Pelton nozzle adjustment mechanism was mounted within the turbine,” explains GUGLER project manager Thomas Berger, who also mentioned that GUGLER had a wealth of experience in the design of horizontal-axis-design 3-nozzle Pelton turbines. Moreover, Berger emphasises that a customer as distinguished as the ÖBB places extremely high demands on its electromechanical equipment. During the complex engineering phase GUGLER gave an impressive demonstration of its calculation expertise. “The ÖBB operate a whole series of large power stations, and apply the same high safety standards to their smaller hydroelectric power facilities. Pressure surge calculations for the Kaponigbach power plant involved using specialised software to dry-run more than 17 distinct scenarios. Having been milled from stainless steel monoblock, turbine runner strength was verified via the finite element method (FEM). FEM simulation was also applied to calculate the strength of the turbine ring and distribution pipes. Evaluation took into account load spectra determined in the pressure surge calculation but also temperature changes and traffic loads”, Berger explains.

© GUGLER

Equipped for all modes of operation

All calculations were checked and approved by the Vienna-based Technical Testing and Research Institute (TVFA). GUGLER’s R&D department conducted model testing at the Vienna University of Technology for a 3-nozzle Pelton turbine. “Turbine design is based on the findings of the test series. This enables us to guarantee maximum efficiency in practice,“ says Thomas Berger. The turbine was designed for an expansion water volume of 900 l/s, a gross head of 211 m and a bottleneck output of approximately 1.6 MW at full load. GUGLER equipped the machine set with a bypass line including a ring piston valve to allow the traction power plant to continue being fed by Kaponigbach River during maintenance work, or if the small power plant went offline. Obervellach II produces traction current only. However, the Kaponigbach power plant was designed to generate electricity at 50 Hz, meaning the small power plant ensures the traction current power plant is self-sufficient and can even feed electricity onto the public grid. Furthermore, Kaponigbach power plant has black start and island operation capabilities so, as Thomas Berger reports, Obervellach II can be reconnected to the grid should there ever be a large-scale blackout: “Load sheddings in island operation were also part of the simulation process to ensure the machine always remained within acceptable frequency fluctuations.”

Regular operation around the corner

The first power plant test runs started at Obervellach II in the autumn of 2023 after a construction phase of around 3½ years. The Kaponigbach power plant was finally commissioned for the first time in the spring of 2024. “Commissioning went off smoothly, and all dry, wet and signal tests were completed successfully. Snowmelt provided enough water to run the turbine at 100 per cent capacity. It was a challenging project all round with multiple interfaces that all now interact seamlessly. We are proud to have successfully provided renowned clients with a solution that meets their very high standards,” Berger summarises. The two new power plants are scheduled to go into regular operation in the summer of 2024. By expanding their domestic hydropower capacities, the ÖBB have clearly underpinned their status as one of the most environmentally friendly rail companies in Europe.