Voith Hydro introduces new M-Line that reduces delivery times by 30%

While extending the product family and range of application of its StreamDiver, Voith Hydro has also been working on further evolving its machine portfolio – with modularised Pelton and Francis turbines. By adapting the machine units into a new kind of building-block system, the new M-Line Series dramatically reduces delivery times to benefit customers. Of course, they can also rely on the new turbines living up to Voith’s proven quality standards.

Delivery time can be a particularly critical factor when it comes to equipping hydropower plants with electromechanical components. For this reason, reduced delivery times were Voith Hydro’s highest priority in developing the latest additions to their portfolio. The key to their solution lies in the modularisation of the Pelton and Francis turbines. “The small-scale hydropower market is highly dynamic. What’s needed today are fast, innovative solutions that ensure high efficiency and reliability. With the M-Line we are setting new standards to meet these new challenges,” as Florian Trost explains. He is “Product Owner” for Francis Turbines at Voith Hydro in St. Georgen. Apart from economic evaluations of existing facilities, his function includes the further development of applied technologies as well as innovation management. One key task consists in developing and defining latest-generation technical standards, and upgrading production methods accordingly.

FOCUS ON DELIVERY TIMES

The faster operators are able to get their machine on the grid, the more likely they are to meet the economic preconditions for operating it successfully. This is why, just like capital costs, short delivery times are emerging as an aspect of growing importance. As Florian Trost explains, “With this particular aspect in mind, we have subjected our developments to numerous tests and optimisations until they showed clear benefits for our customers.” In addition to enjoying economic advantages, customers benefit especially from the significantly shorter lead times compared to individually constructed facilities. Further advantages include lower transportation and installation requirements, as the electrical engineering components and balance-of-plant equipment are pre-assembled at the factory.

M-LINE – MODULAR SOLUTIONS FOR POWER PLANTS

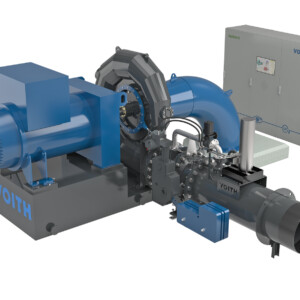

The new M-Line is designed as simplified, maximally standardised turbine-generator- units, which come complete with the required auxiliary systems. As the system is fully pre-assembled, it arrives at the power station as a compact ‘ready-made’ unit. This means it can be installed on-site and taken into operation right away. Together with the electrical equipment, the M-Line therefore provides a comprehensive, compact and reliable ‘water-to-wire’ system. “There’s a lot of our engineering know-how, as well as decades of experience in turbine construction and latest insights from our R&D centre in every single facility we help to build – and the same is true for our M-Line Series. When it comes to the quality of our components, we’ll never compromise,” as Florian Trost asserts. This is why the same – or at least nearly the same – hydraulic contours are used for small-sized turbine versions as for larger facilities. This way, Voith is able to guarantee ultimate performance and a high level of investment protection. All components and production steps are subject to Voith Hydro’s notoriously stringent quality controls.

INFORMATION ADVANTAGE FROM THE START

At project kick-off, the customer is provided with an application diagram, which indicates whether an M-Line Turbine is suitable for the job. Taking into account the head and flow capacity, the application diagram provides a simple readout of the optimal size. Based on the resulting recommended layout, the power station project is ready to advance to the planning stage straight away. If there are two possible layouts for a particular use case, the Voith Hydro team assists with its trusted expert advice in deciding on a final concept.

AUTOMATION SYSTEMS

The automation system offers a standardised low-voltage and medium-voltage platform for all M-Line products. The underlying design concept minimises complexity by focussing only on the essentials. Additional functions and systems are available as further options to meet local grid-specific requirements or customer needs.

M-LINE PELTON

The M-Line Pelton turbine is designed for heads from 80 m to 340 m and a flow rate of up to 1.60 m3/s. Following an initial customer assessment, Voith Hydro’s experts optimise the turbine size as well as the rotor and nozzles. This gives the M-Line a modular, standardised design that can still be tuned to individual project requirements in order to ensure optimum performance. To simplify the next steps in the project, the turbine is then pre-assembled at Voith Hydro’s facilities. There it is prepared for transport in five modules: generator, casing, HPU (hydraulic power unit), intake valve, and automation system. Transport is much easier this way, and on-site work is greatly reduced as well. Only a single concreting step is required once the turbine is fully assembled.

M-LINE FRANCIS

The M-Line Francis turbine is designed for applications with heads of 20 m to 80 m and a flow rate of up to 3.80 m3/s. It is also pre-assembled at the factory and then prepared for transport in four modular parts: intake, turbine, suction pipe and automation system. Factory testing and the configuration of the electrical components are completed at Voith’s facility in St. Georgen. The M-Line Francis turbine also requires only a single concreting step once it is fully assembled. This way, it is ready to be taken into operation within a very short time.